- Get in Touch with Us

Last Updated: Apr 25, 2025 | Study Period: 2022-2030

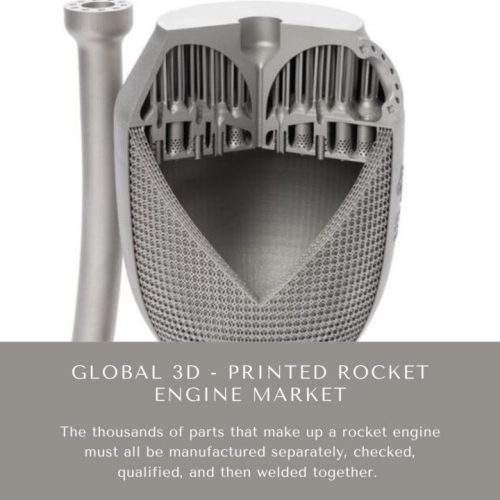

The thousands of parts that make up a rocket engine must all be manufactured separately, checked, qualified, and then welded together. The engine was pushed as a single unit by our team using 3D printing technology. There are no assemblies and no traditional integration process.

The global 3D - printed rocket engine market accounted for $XX Billion in 2021 and is anticipated to reach $XX Billion by 2030, registering a CAGR of XX% from 2022 to 2030.

Space technology startup Agnikula announced the opening of Rocket Factory-1, the country's first-ever rocket factory specializing in mass-produced 3D printed space engines.

A metal 3D printer and a variety of other equipment are housed in Agnikul's Rocket Factory-1, which enables end-to-end rocket engine manufacturing under one roof. Two rocket engines each week can be produced at the factory.

Agnikul had a contract with EOS as the latter's engine 3D printing partner.

In order to advance 3D printing of rocket engines all the way to space qualification, also known as Technology Readiness Level 9, which is once a technology has been "flight-proven" during a successful mission, Agnikul will also install an EOS M400-4 printer in its facilities.

Additionally, Agnikul will rely on EOS' Additive Minds technical consulting services.

Launching a 3D printing business for space technologies, X Bow has come out of stealth mode.

The firm has already developed a portfolio of tiny launch vehicles suited for orbital and suborbital missions. The company specializes in the production of 3D printed solid fuels and rocket motors.

Designing and 3D printing their own solid rocket motors has been the main emphasis of X-Bow. The company asserts that its launch engines are more flexible, dependable, and responsive than conventional rocket engines while also being more cost-effective.For a variety of government and commercial clients over the past six years, X-Bow has developed an ever-expanding product line of 3D printed rocket engines, additively built propellants, and end-to-end launch services.

| Sl no | Topic |

| 1 | Market Segmentation |

| 2 | Scope of the report |

| 3 | Abbreviations |

| 4 | Research Methodology |

| 5 | Executive Summary |

| 6 | Introduction |

| 7 | Insights from Industry stakeholders |

| 8 | Cost breakdown of Product by sub-components and average profit margin |

| 9 | Disruptive innovation in the Industry |

| 10 | Technology trends in the Industry |

| 11 | Consumer trends in the industry |

| 12 | Recent Production Milestones |

| 13 | Component Manufacturing in US, EU and China |

| 14 | COVID-19 impact on overall market |

| 15 | COVID-19 impact on Production of components |

| 16 | COVID-19 impact on Point of sale |

| 17 | Market Segmentation, Dynamics and Forecast by Geography, 2022-2030 |

| 18 | Market Segmentation, Dynamics and Forecast by Product Type, 2022-2030 |

| 19 | Market Segmentation, Dynamics and Forecast by Application, 2022-2030 |

| 20 | Market Segmentation, Dynamics and Forecast by End use, 2022-2030 |

| 21 | Product installation rate by OEM, 2022 |

| 22 | Incline/Decline in Average B-2-B selling price in past 5 years |

| 23 | Competition from substitute products |

| 24 | Gross margin and average profitability of suppliers |

| 25 | New product development in past 12 months |

| 26 | M&A in past 12 months |

| 27 | Growth strategy of leading players |

| 28 | Market share of vendors, 2022 |

| 29 | Company Profiles |

| 30 | Unmet needs and opportunity for new suppliers |

| 31 | Conclusion |

| 32 | Appendix |