- Get in Touch with Us

Last Updated: May 20, 2025 | Study Period: 2024-2030

Magnet wire is an insulated copper or aluminum conductor used to wind motors, transformers, generators, and any other electrical device where electrical energy is converted to mechanical energy. Round shaped magnet wires are the fastest growing shape type of magnet wires in Dedicated Hybrid Transmission (DHT)

To know more about Global EV Traction Motor Market, read our report

The Global Superyacht Market can be segmented into following categories for further analysis.

The Global Electric Vehicle Magnet Wire Market accounted for $XX Billion in 2023 and is anticipated to reach $XX Billion by 2030, registering a CAGR of XX% from 2024 to 2030.

The establishment of a global joint venture was announced by Superior Essex Inc. ("Superior Essex"), the parent company of Essex Magnet Wire, and Furukawa Electric Co., Ltd. ("Furukawa"), two pioneers in the development of magnet wire products and customised solutions. A global market leader will be created through the joint venture, which will build on an earlier magnet wire relationship.

The combined business will use the "Essex Furukawa" trademark and conduct business as Essex Furukawa Magnet Wire LLC. Essex Furukawa's customers should gain from significant synergies, such as the expansion of custom product solutions, the sharing of best practises, and the capacity to better serve customers with additional points of shipping, expanded global sales and technical teams, increased global rod & foundry resources, and a diversified global innovation team, especially for EV/HEV developments.

With commanding market presence in North America, Europe, Asia, and Japan, significant customer alliances, and accelerated research and development developments, the new worldwide joint venture will enable Essex Furukawa to lead the industry in technological advancements.In addition to providing all of our clients with a more extensive worldwide network across three continents, Essex Furukawa will continue to provide the same reliable, high-quality products with cutting-edge technology, particularly for electric vehicles.

Although Essex Furukawa may explore optimal reorganisation to offer a superior value to customers, there won't be any immediate or significant changes to the organization's relationship with customers. The establishment of Essex Furukawa will not affect how either firm honours its present obligations.

Rectangular wire allows the engineer to design a motor with more copper in the unit. Round wire has more voids between the wires in the windings.

In terms of the coils of driving motors, the distributed winding method of round wires (whose cross section is round) and the concentrated winding method of rectangular wires (whose cross section is rectangular) used to be mainstream winding methods. Recently, the method trend is moving to the distributed winding method for rectangular wires as the technology advances.

Aluminum magnet wires are the fastest growing type of magnet wire market. These are used in applications for their various properties such as high mechanical strength, abrasion resistance, and high dielectric performance.

Regarding the disadvantage of distributed winding motors (i.e., the coil end height is higher than that of concentrated winding motors), the coil end height is reduced to a level equivalent to that of concentrated winding motors by inserting a rectangular wire, which is divided into specified segments, into the iron core and then welding the edge for assembly.

Also, the use of rectangular wires has significantly improved the space factor. This achieves downsizing of the size, along with reductions in weight and loss due to the reduced amount of copper being used. The overall efficiency of the motor also increases due to the better space factor provided by rectangular wires.

In line with the advancement of motors, magnet wires must meet the following requirements:

Inverter drive systems are used for driving motors for EVs. For some motors, the motor operation voltage has been increased by twice or more from the initial voltage.At the coil end, it is necessary to ensure the insulation of magnet wires corresponding to the interphase voltage. Insulating members, such as interphase paper, were used in conventional products, but the increased thickness of the insulation film reduces such insulating members, making it possible to achieve downsizing and cost reduction.

Suppliers have looked into the uniform distribution of insulation film thickness for rectangular wires and developed a low-permittivity structure film whose insulation performance is higher than that of conventional film. The characteristics are excellent in terms of the resistance to degradation of wire treatment.Meanwhile, the motor rotation has been increased to achieve downsizing and high-power output. For some motors, their rotation has been almost tripled from that of early products. High motor rotation requires an increased drive voltage. The high-insulation performance films that we have been developing, as mentioned earlier, contribute to increasing the rotation

The decreasing wire used while increasing the efficiency of the wires is the main goal of suppliers. Wiring and magnets used in motors use minerals that are becoming increasingly scarce in supply which will cause issues in the supply chain. Recycling copper utilized as magnet wires as well as improving technology to reduce usage per motor will be of prime importance especially as EVs are gathering traction across various regions

The magnet wire market is 10-13 % of the traction motor market, as most of the value comes from the traction motor industry and usage across other vehicle components is lower than traction motor.Magnet wire growth will be dependent mainly on growth in traction motors across the globe, increase in power of traction motors and development of wires to handle temperature, and power, decrease size, and increase efficiency.

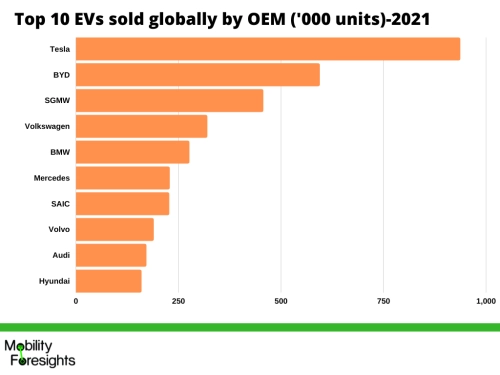

Tesla Model 3 took the lead globally among battery electric vehicles followed by Wuling Mini and Tesla Model Y. Among the top 5 models, 2 were occupied by Tesla showcasing their global dominance.

China and Europe were the primary regions with battery electric vehicle sales surpassing 2020 sales. Chinese OEMs have a strong sales base at home and are looking to go abroad with their sales especially in regions with low EV sales as their EVs are lower in cost compared to other EVs.

The first 4 months of 2021 already showcased that the market is growing and is expected to overrun 2020 sales

Tesla led among the brand sales globally followed by Volkswagen, BYD, SGMW, and Volkswagen. The brands except for Tesla and Nio offer a mix of PHEVs and BEVs.

All OEMs will look to offer BEVs in the next 2-3 years to establish themselves for the change upcoming in the next 20 years where at least 40% of the new car sales will become plugged in.

Suppliers have come up with products for this shift and are also researching on developing new technology. The supply chain for products across electric vehicles is also being developed intensively looking into long-term deals especially among battery suppliers.

Factories across the world had to stop production due to chip shortage which is another aspect OEMs and suppliers will look closely into so that the recurrence doesn’t occur.

In 2021-, Wuling Mini EV lead the sales followed by Tesla Model Y, Tesla Model 3, Qin Plus and Li Xiang One EREV

Tesla Model 3 saw sales mainly from Tier 1 and 2 cities, so did GAC Aion S. Wuling Mini EV saw sales mainly from Tier 4 and 5 cities. Of overall plugged-in vehicle sales, Tier 1 cities held 37%, Tier 2 held 21%, Tier 3 held 15%, Tier 4 held 14% and Tier 5 held 12%. The Chinese market is mainly held by domestic OEMs.

Due to COVID, the subsidies that were supposed to be phased out this year were extended for 2 more years at a 10% decrease every year. China also has a strong base for electric commercial vehicles and their OEMs such as BYD, Yutong, etc. are supplying electric buses globally even in regions such as Chile which have a weak electric vehicle market.

Supporting infrastructure such as charging stations and battery swapping are set up across the country. China is one of the countries with companies focusing on battery swapping to save time utilized at charging stations.

The long-term feasibility and condition of battery supplied are to be looked out for as the business model is currently unchallenged on various aspects.

While all regions across the globe saw a decrease in automobile vehicle sales due to COVID, Europe saw a rise in plugged-in vehicle sales mainly due to the incentives and subsidies that were offered across many countries.

Euro NCAP is also a motivating factor for OEMs to increase electrification among their fleet hence develop various plugged-in vehicles and also full electric vehicles. Cities are coming up with zero carbon emission rules thereby increasing electrified vehicle sales. Electrified vans will also see increased sales mainly among major city centers.

Europe is also seeing an extensive increase in charging networks and more focus is placed on 100+kW chargers across countries. Ionity is setting up 400 charging stations across European highways with 350 kW chargers. Governments have put in the effort to develop charging stations by offering subsidies and lowering electricity rates for charging stations.

800v architecture reduces the copper winding wire diameter, which decreases the overall volume as well as increases the packing efficiency, allowing for smaller motors.

The same lower current requirements in an 800-V system reduce not just the motor copper losses, but loss in the entire system wiring loom, introducing weight, space, and cost savings.

LS Cable & Systems was the first to produce 800V high voltage magnet wire in Korea.LS Cable & System’s branches are expanded to almost every continent

In 2023 February, Dahrentrad , LWW Group and Isodraht unified under Dahren

Essex Furukuwa is a global joint venture company between Superior Essex Inc. and Furukawa Electric Co., Ltd. This joint venture will allow Essex Furukawa to lead the industry in technological advancements ,have market command positions in North America, Europe, Asia, and Japan

| Sl No | Topic | Slide Number |

| 1 | Market Segmentation | 6 |

| 2 | Research Methodology | 8 |

| 3 | Executive Summary | 10-16 |

| 4 | Global EV Magnet Wire Manufacturing Locations | 18-19 |

| 5 | Potential Opportunities for Bekaert in EV Magnet wire market | 21 |

| 6 | Key Criteria For Magnet Wire Vendor Selection | 23 |

| 7 | Key Attributes of Magnet Wire in Electric Vehicle application | 25-29 |

| 8 | Growing popularity of E-axle and Impact on EV magnet wire market | 31 |

| 9 | Usage of Magnet wire in Dedicated Hybrid Transmission Market | 33-34 |

| 10 | Top 10 EV platforms -2022 | 36-51 |

| 11 | EV Product Plan | 53-62 |

| 12 | Current Obstacles affecting magnet wire performance | 64 |

| 13 | Magnet Wire Insulation Overview | 66 |

| 14 | Polymer Usage Trends in Magnet Wire Insulation - 2022 | 68-69 |

| 15 | New Product Development in Magnet Wire Enamel by Chemical Companies | 71-74 |

| 16 | New product development in EV traction motor market and its impact on magnet wire | 76-77 |

| 17 | Margin variation between insourced vs outsourced traction motor magnet wire | 79 |

| 18 | Current & Upcoming EVs with 800V Architecture and its Impact on Magnet Wire | 81-86 |

| 19 | Magnet wire content in EV, by EV & Motor Type – 2022 | 88-89 |

| 20 | Market Size, Dynamics and Forecast By Geography, 2022-2030 | 91-103 |

| 21 | Market Size, Dynamics and Forecast By EV type, 2022-2030 | 105-110 |

| 22 | Market Size, Dynamics and Forecast By Motor Type, 2022-2030 | 112-117 |

| 23 | Market Size, Dynamics and Forecast By Wire Shape, 2022-2030 | 119-122 |

| 24 | Market Size, Dynamics and Forecast By Application, 2022-2030 | 124-127 |

| 25 | Competitive Landscape | 129 |

| 26 | Growth Strategy of Major Players | 131 |

| 27 | Market Share of Major Magnet Wire Suppliers-2022 | 133 |

| 28 | OE-Supplier Alignment (Motor-Wiring suppliers) | 135-140 |

| 29 | Mergers and Acquisition in recent years | 142-143 |

| 30 | Company profiles | 145-154 |

| 31 | Conclusion | 156 |