- Get in Touch with Us

Last Updated: Apr 25, 2025 | Study Period: 2024-2030

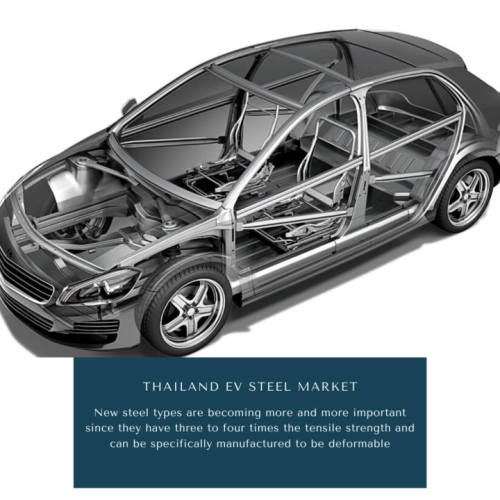

High-strength steel brands are a crucial component of modern, ecologically friendly lightweight construction as opposed to aluminum and carbon. They reduce the weight of the vehicle by a large percentage.

High-strength and ultra-high-strength steels' prowess over single-material solutions in fiber composites, titanium, and aluminum is highlighted by their capacity to reconcile this spectrum of requirements with the need for reduced weight and lower manufacturing costs.

Passenger safety is still given high attention in vehicle design whether a car is conventionally powered or an electric vehicle. New steel types are becoming more and more important since they have three to four times the tensile strength and can be specifically manufactured to be deformable.

The Thailand EV Steel Market accounted for $XX Billion in 2021 and is anticipated to reach $XX Billion by 2026, registering a CAGR of XX% from 2024 to 2030.

Technicians at one of Nippon Steel's research facilities spend their days ramming numerous electric and hybrid vehicles into walls and other obstructions. Despite the never-ending testing, there is no violent reverberations or a shriek from twisted metal.

This is due to the fact that every crash occurs in a virtual setting. The quest for lighter, more durable, and robust materials is intensifying as the EV market grows.

The Steel Research Laboratories of Nippon Steel employ virtual reality to dissect the automobile body into fragments as small as a few square millimeters in order to study the impact of crashes.

Depending on the kind and type of steel being used, Nippon Steel's unique algorithm can determine the strain brought on by the impact.

The application can measure the force applied to the vehicle part to determine its stiffness and fracture risk. In order to adapt to the more cutthroat competition in the materials sector brought on by the EV age, Nippon Steel will use its data.

The corporation has begun actively urging manufacturers all around the world to take part in collaborative tests. The primary source of revenue for steel producers is steel sheets for the automobile sector.

The simulated crash test data will be used by Nippon Steel to create steel that can compete with aluminum. Steel sheets with ultra-high tensile strength might be an option.

| Sl no | Topic |

| 1 | Market Segmentation |

| 2 | Scope of the report |

| 3 | Abbreviations |

| 4 | Research Methodology |

| 5 | Executive Summary |

| 6 | Introduction |

| 7 | Insights from Industry stakeholders |

| 8 | Cost breakdown of Product by sub-components and average profit margin |

| 9 | Disruptive innovation in the Industry |

| 10 | Technology trends in the Industry |

| 11 | Consumer trends in the industry |

| 12 | Recent Production Milestones |

| 13 | Component Manufacturing in US, EU and China |

| 14 | COVID-19 impact on overall market |

| 15 | COVID-19 impact on Production of components |

| 16 | COVID-19 impact on Point of sale |

| 17 | Market Segmentation, Dynamics and Forecast by Geography, 2024-2030 |

| 18 | Market Segmentation, Dynamics and Forecast by Product Type, 2024-2030 |

| 19 | Market Segmentation, Dynamics and Forecast by Application, 2024-2030 |

| 20 | Market Segmentation, Dynamics and Forecast by End use, 2024-2030 |

| 21 | Product installation rate by OEM, 2023 |

| 22 | Incline/Decline in Average B-2-B selling price in past 5 years |

| 23 | Competition from substitute products |

| 24 | Gross margin and average profitability of suppliers |

| 25 | New product development in past 12 months |

| 26 | M&A in past 12 months |

| 27 | Growth strategy of leading players |

| 28 | Market share of vendors, 2023 |

| 29 | Company Profiles |

| 30 | Unmet needs and opportunity for new suppliers |

| 31 | Conclusion |

| 32 | Appendix |